Turbine diesel fuel filter

Turbine Diesel Fuel Filter / Water Separator Operation

What is a Turbine Diesel Fuel Filter / Water Separator?

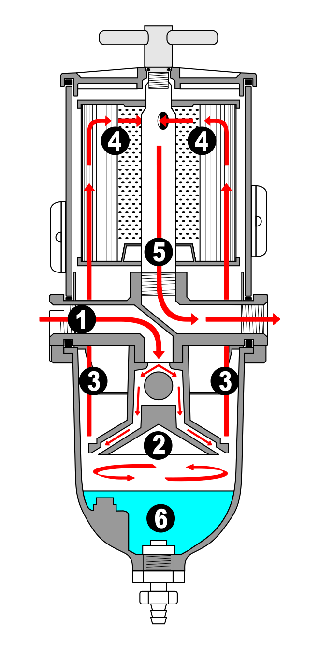

The filter gets its name by virtue of the way it functions. The illustration on the right and the corresponding numbered description will explain its operation and thus its apt moniker.

1) Unfiltered fuel enters the filter and travels straight down, past the back flow check ball valve, into the Turbine assembly.

2) Fuel exits the Turbine assembly in a spinning motion, creating a centrifuge effect. Heavier particles and water droplets are separated from the fuel and fall into the collection bowl.

3) Fuel rises to fill the upper chamber of the filter and surround the outside of the element.

4) Fuel passes through the element as contaminants and water are filtered out. Water droplets form on the element surface, coalesce, and fall into the collection bowl for later removal.

5) Filtered fuel enters the main fuel tube and travels straight down the filter and out to the fuel pump.

6) Contaminants not trapped in the element media and separated water gather in the collection bowl at the bottom of the filter. A drain valve at the bottom of the bowl can be opened to allow for their removal.

The heart of any diesel fuel filter / water separator is the element. Always use a quality element with a water separating filtration media like Griffin’s MICROBLOC® or Racor’s AQUABLOC®. Using quality elements is the best way to maximize the efficiency of your fuel filter and protect your investment.